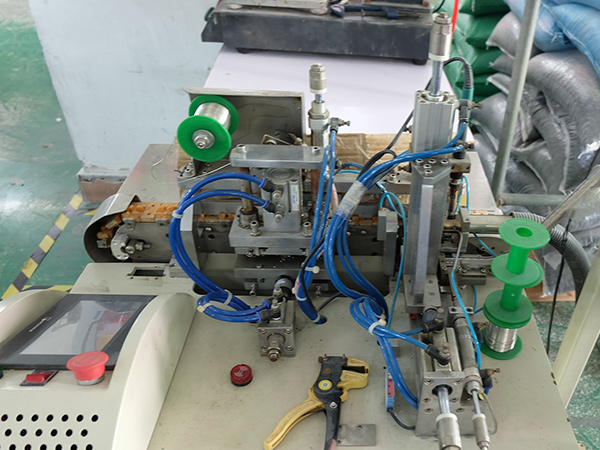

USB Cable factory production machine

Did you know that manufacturing a mobile phone usb cable involves a fascinating array of machinery? Let’s take a closer look at the process.

🔧 The Essential Machines for Data Cable Production:

- Cable Cutting Machine: For precision cuts to the exact length needed.

- Weaving Machine: To wrap the cable in a protective layer for added durability.

- Molding Machine: Forms the shape of the cable’s connectors for device compatibility.

- Oil Coating Machine: Applies a layer of oil to extend the cable’s life.

- Soldering Machine: Bonds the wire to the connector for a secure connection.

- Spark Machine: Ensures the cable’s insulation meets safety standards.

- Gluing Machine: Applies adhesive to reinforce the cable’s structure.

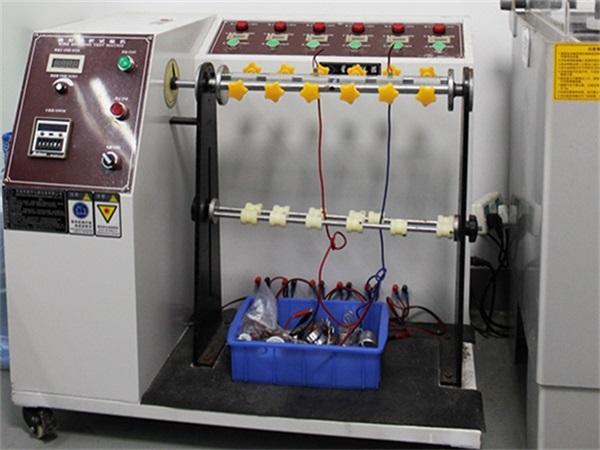

And that’s not all! Quality control is just as crucial:

- Testing Machine: To check the functionality of the cable.

- Swing Test Machine: To simulate real-life movements and test the cable’s durability.

- Salt Spray Test Machine: To assess the cable’s resistance to corrosion.

🔬 Have you encountered any of these machines in your professional experience?

Which ones are you familiar with, and which have you had the chance to see in action? Share your stories and insights in the comments below!

Let’s work Together…

Cheers…🌱🌱

WhatsApp:+86 136 5268 3407

Email: linda@leweiyicn.com

#DataCableProduction #ManufacturingProcess #IndustrialMachinery #QualityControl#Cable #usbcable #machanie #production #cablefactory #leweiyi

Leave a comment